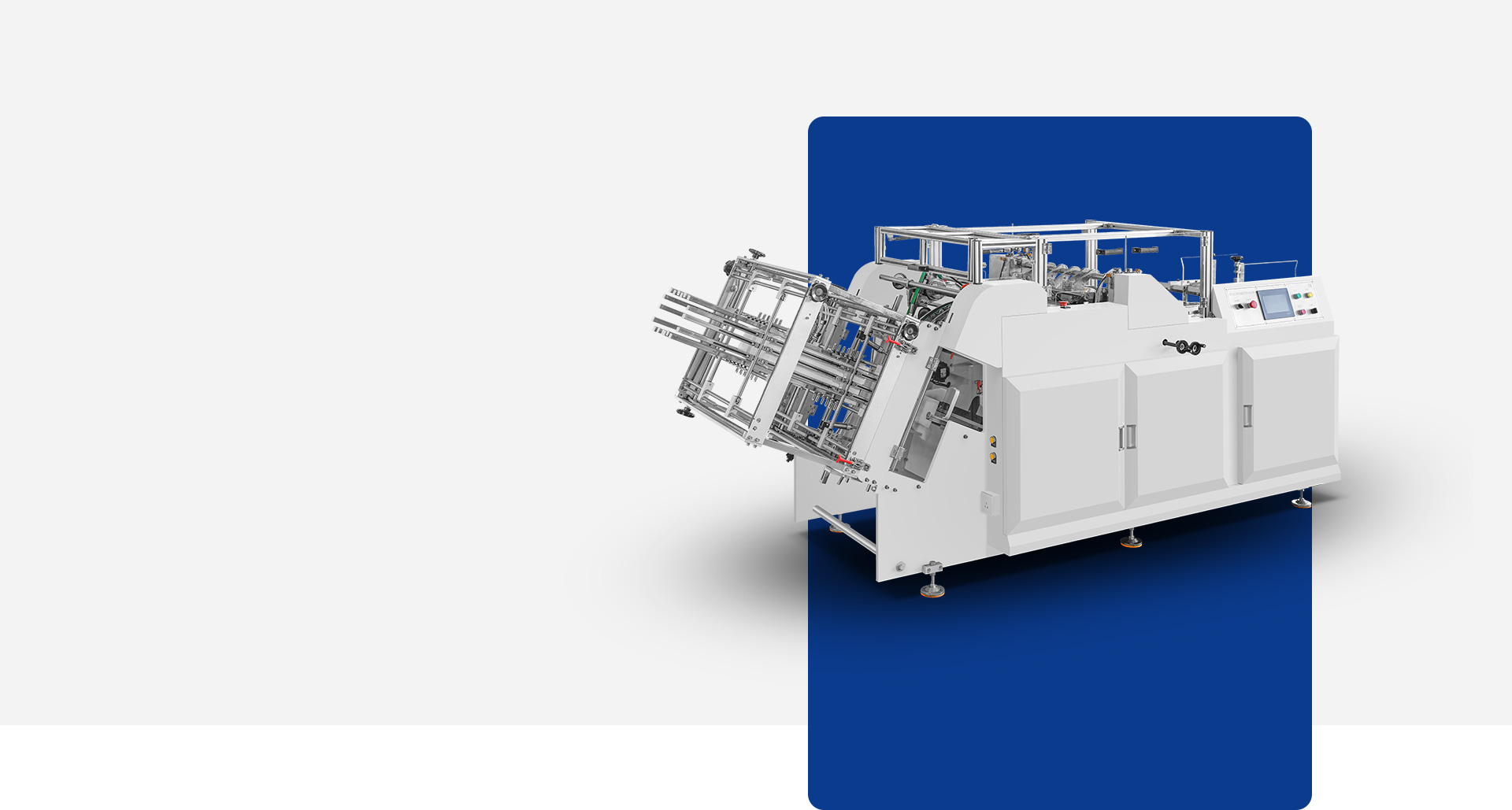

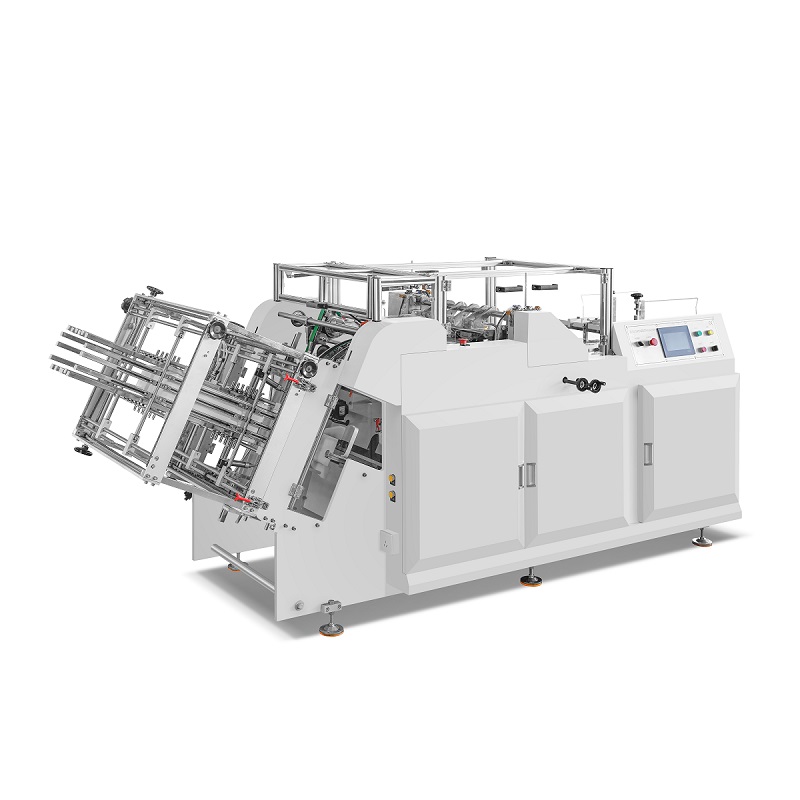

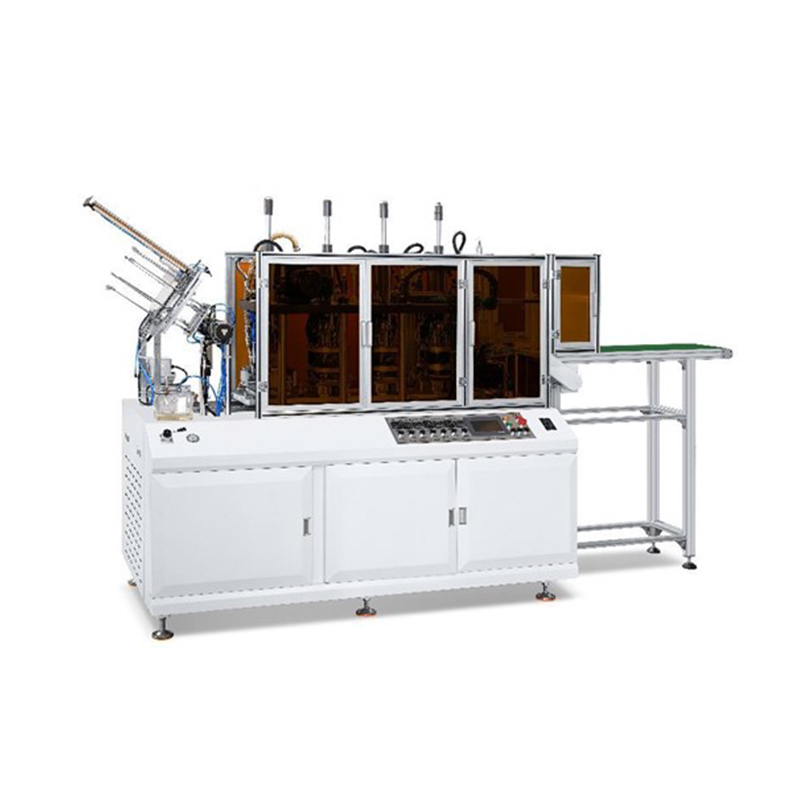

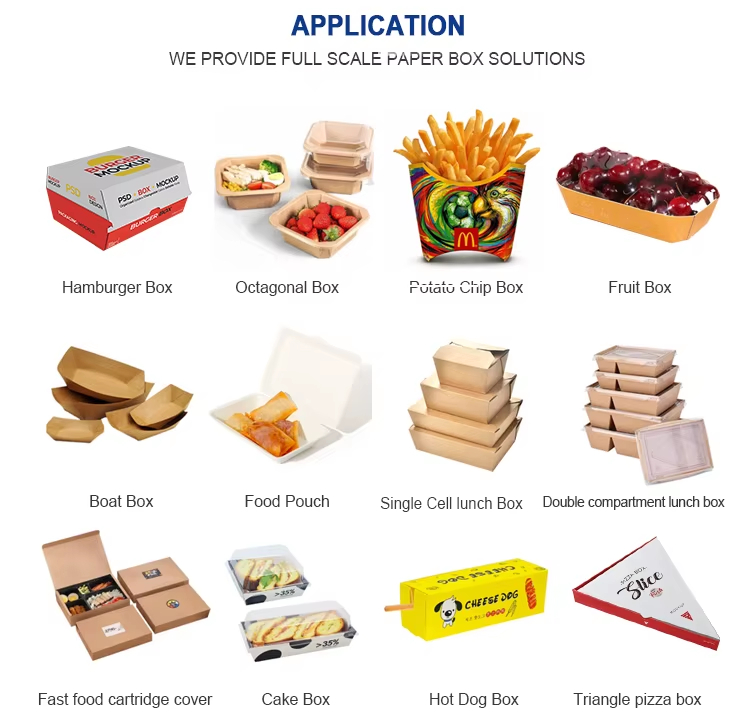

ZX-2000 high speed double-lane paper box machine stands out as a core piece of equipment for large-scale production. Built for high output, it excels at rapidly forming fast-food boxes and complex-shaped cartons like burger boxes, triangular pizza boxes, and takeaway containers. It perfectly meets the modern food industry's dual demands for efficiency and variety.

Key Features & Benefits:

High-Efficiency Dual-Lane Design: Its vertical, double-lane structure allows simultaneous forming of two boxes, dramatically boosting production efficiency. With a capacity of up to 12,000 units per hour, it is ideal for continuous, high-volume orders.

Precision Handling of Complex Shapes: Equipped with adjustable molds and an intelligent control system, it easily manages the special shaped boxes like burger and triangular pizza boxes, ensuring precise, consistent forming and reducing material waste.

Fully Automated Operation: The process is automated from paper feeding and forming to box ejection. This lowers labor costs while guaranteeing a stable output of high-quality boxes, ensuring hygiene and safety for food packaging.

This machine is widely used in fast-food chains, food processing, and the delivery industry, providing a fast and reliable packaging solution for items like burgers, pizza, and desserts. It helps businesses respond more swiftly to market needs.

In summary, with its high efficiency, precision, and automation, the highs peed double-lane paper box machine is a key asset for fast-food and specialty box production, driving the packaging industry towards smarter and more sustainable development.