Servo motor control the forming mold (press mold)

Using full servo system (4 servos in machine replace cam system)

Easy exchange molds to make different products, charging and adjusting time is very short.

PLC program control the whole line, available to make complicated boxes.

Automatic collection, stock, and count.

Model: ZX-1600

Paper Weight: 200-620g

Speed: 60-160pcs/min(one station)

MAKE A QUOTE

MAKE A QUOTE

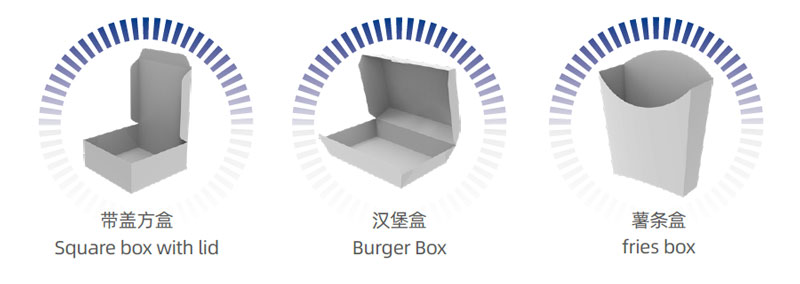

ZX-1600 Carton Erecting Machine is specially designed to produce a variety of food containers, such as hamburger boxes, hot dog trays, single piece boxes, Chinese takeaway boxes, French fry boxes, lunch boxes and meal boxes. Materials include cardboard, paper, paperboard and corrugated paper.

|

|

|

|

|

|

|

Model |

ZX-1600 |

||

|

Paper Weight |

200-620g |

||

|

Speed |

60-160pcs/min(one station) |

||

|

Welding Method |

Water-Glue System Welding; |

||

|

Available Material |

200~620gsm board, paperboard, paper, corrugated cardboard, Fluted paper, etc. |

||

|

Material Thickness |

Max. 1.5mm |

||

|

Paper Size: |

|

L=Length: 100-450mm |

|

|

W=Width: 100-550mm |

|||

|

H=Height: 15mm-320mm |

|||

|

Angle: 5~50 degrees |

|||

|

Paper Thickness |

≤1.6mm |

||

|

Paper Size |

500*480 |

||

|

Machine Size (L*W*H) |

3600*1850*1700mm |

||

|

Power Source |

3-phase, 380V, 50/60Hz |

||

|

Voltage |

380v/220v |

||

|

Current |

50hz |

||

|

Total Power |

5kw |

||

|

Machine Weight |

2000kg |

||

|

Air Source |

Compressed air at 6-10 bar needed |

||

|

The product complies with the regulatory requirements and standards on CE conformity andtherefore carries the CE mark. |

|||

|

|

|

|

Thick Walls Machine weight is exceed 2800kgs, machine runs stably at a high speed. Cam Pushing System Cam pusher design, reduce the wearing a lot. Belt Structure Belt structure have features of low noise, easy maintenance, longer service life and high precision |

|

We are using same structure as the folder glue machine, the paper will be delivered more smoothly. And hard aluminium material, much better and use imported belt, the machine will stop if the machine doesn’t delivery paper or the machine is not in a correct way, we are also using servo motor for feeding. |

|

At the beginning of paper feeding part, we install the vibrator, the quality of the output products will be increased when feeding precision is high, and it can make paper feed more smoothly. |

|

We are using 4 servo system - two servo motors for paper feeding, one servo motor for paper sending, one servo motor for molding. The structure is much easier and it has less damageable parts with lower maintenance cost, you could do the most adjustments by Touch Screen Program PLC. If you only run the single lane, you could turn off the second lane, they are independent. |

|

Wheel Glue System – they are independent. |

|

In the forming part, we have the lubrication system and use the two rails which can make the forming more stably and longer service life. |

|

We improve this structure, you could do changes faster than others, the collection unit could be open when you change the molds. |

|

Two collection units are independent, you can move it smoothly. |

GET A QUOTE

+86-13780131993