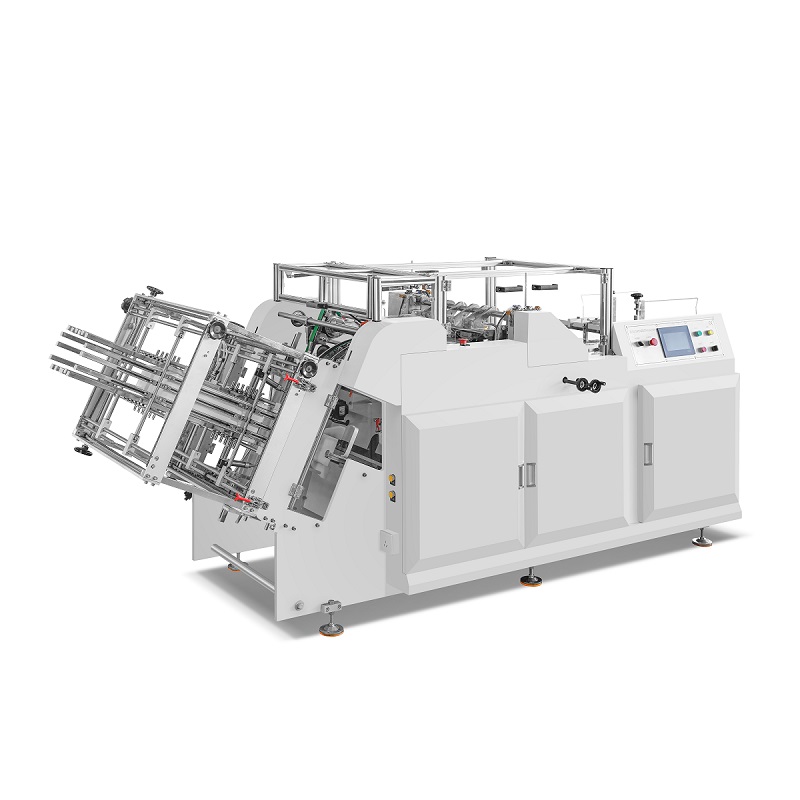

A Carton Erecting Forming Machine, also referred to as a carton erector or case erector, is an automated packaging system designed to transform flat corrugated cardboard blanks into fully formed, three-dimensional cartons ready for product filling and sealing. This machine plays a pivotal role in modern manufacturing and logistics by streamlining the labor-intensive process of manual carton assembly. Here's a detailed breakdown:

Core Functionality

-

Automated Carton Formation

The machine automatically picks flat carton blanks from a magazine, unfolds them into their box shape, and secures the bottom flaps using either adhesive glue or pressure-sensitive tape 319. This eliminates the need for manual folding and taping, reducing labor costs and human error. -

Precision Engineering

Advanced mechanisms, such as vacuum suction cups, servo motors, and PLC-controlled systems, ensure consistent and accurate carton erection. For example, suction cups lift and position the blanks, while mechanical arms fold the flaps into place 719. -

Sealing Options

- Taping: A tape head applies tape to the bottom flaps for quick, reliable closure.

- Gluing: A gluing unit dispenses food-grade or industrial adhesive (e.g., cold or hot melt) to bond the flaps 37.

Key Components

-

Unscrambler/Feeder: Separates and feeds individual flat blanks into the forming section.

-

Forming Mechanism: Guides and folds the blanks into shape using rollers, guides, and folding plates.

-

Sealing Unit: Tapes or glues the bottom flaps.

-

Conveyor System: Transports formed cartons to the next production stage (e.g., filling or sealing) 316.

-

Control Panel: Allows operators to adjust settings for different carton sizes and monitor performance via a touchscreen interface 919.

Types and Automation Levels

-

Fully Automatic Carton Erectors

- Require minimal human intervention.

- Handle diverse carton sizes (adjustable via sensors or servo motors) and operate at high speeds (e.g., 12–36 cartons per minute) 613.

- Ideal for high-volume industries like food, pharmaceuticals, and e-commerce.

-

Semi-Automatic Carton Erectors

- Need manual loading of blanks or partial operator assistance.

- Suitable for smaller operations or variable carton sizes 1319.

-

Specialized Models

- Rigid Box Erectors: For luxury packaging (e.g., gift boxes).

- Robotic Erectors: Use robotic arms for complex or heavy-duty applications 1926.

Applications

-

Food & Beverage: Forms boxes for snacks, frozen foods, and beverages, often using food-grade adhesives 721.

-

Pharmaceuticals: Ensures sterile, tamper-proof packaging for medicines.

-

E-Commerce: Handles high-volume order fulfillment by rapidly erecting shipping cartons.

-

Manufacturing: Packages electronics, automotive parts, and household goods 516.

Benefits

-

Efficiency:

- Forms cartons up to 3x faster than manual labor (e.g., 12–36 cartons per minute vs. 3–4 by hand) 613.

- Reduces downtime with quick size changeovers (e.g., 7 minutes for some models) 6.

-

Cost Savings:

- Lowers labor costs by replacing manual workers.

- Minimizes material waste through precise folding and sealing 321.

-

Consistency:

- Ensures uniform carton quality, reducing defects and product damage during transit 319.

-

Safety:

- Eliminates repetitive manual tasks, reducing ergonomic risks 319.

Integration with Packaging Lines

Carton erectors often work seamlessly with other machines, such as case sealers, labelers, and case packers, to create fully automated packaging lines. For example, a case study showed that integrating a carton erector and sealer increased productivity by 400% while reducing labor requirements by 300% 21.

Maintenance and Longevity

Regular maintenance, including lubrication, gear oil changes, and sensor checks, ensures optimal performance. With proper care, these machines can operate reliably for years, even in high-demand environments 2526.

In summary, a Carton Erecting Forming Machine is a cornerstone of modern packaging, offering speed, precision, and scalability across industries. By automating carton assembly, it enhances operational efficiency, reduces costs, and ensures products are securely packaged for distribution.