In today's packaging industry where maximizing efficiency is paramount, speed and reliability define a machine's true value. The double-station carton erecting machine stands out by redefining productivity benchmarks for automated packaging equipment. It delivers a stable output of up to 360 cartons per minute,a rate that not only surpasses traditional single-station machines but also significantly outperforms many comparable models on the market.

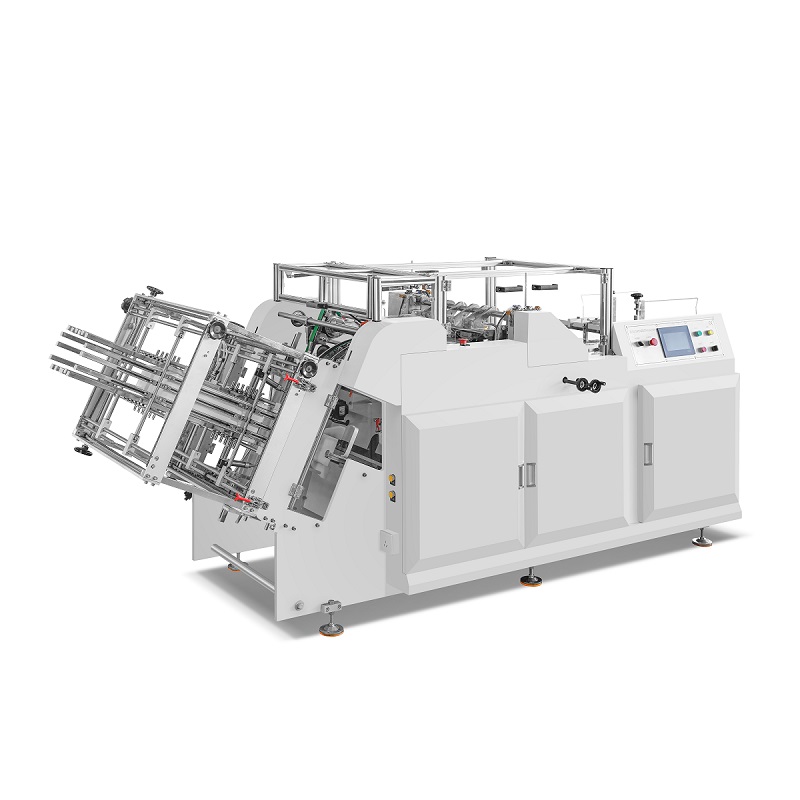

This remarkable efficiency is driven by two key design innovations. First, its dual-station parallel processing system serves as the foundation for high-speed production. Both stations operate simultaneously in a continuous cycle, effectively integrating the output of two high-performance machines into one compact unit. Second, a full servo-motor drive system provides robust power and millisecond-level precision, ensuring every step—from feeding and folding to forming—remains accurate even at this rapid pace, guaranteeing consistent product quality.It is worth mentioning that the dual stations can also operate independently, allowing one side to change molds without affecting the production on the other side, which can be flexibly adjusted according to the order volume.

Notably, the ZX-1600 double-station carton erecting machine achieves full automation from paperboard feeding to finished carton stacking. This feature eliminates labor dependency, significantly reduces labor costs, and removes management burdens caused by manual operations. More importantly, it overcomes production bottlenecks and quality inconsistencies resulting from human rhythm variations, thereby enabling consistent and stable output at 360pcs per minute.

In summary, with its high-speed output of 360 cartons per minute, innovative dual-station parallel operation, and fully automated workflow requiring no manual setup, this double-station carton erecting machine offers packaging businesses a powerful solution to dramatically increase productivity, lower operational costs, and maintain high-quality standards,making it an ideal choice for handling large-volume orders and tight deadlines.