Introduction

The fast-food industry is undergoing a massive transformation in packaging efficiency. With rising labor costs, sustainability demands, and the need for faster production, major chains like McDonald's, KFC, and Burger King are increasingly adopting automatic fast food box making machines. But what’s driving this shift? This article explores the key reasons behind the trend and how automated packaging machines are revolutionizing the industry.

1. Rising Labor Costs & Operational Efficiency

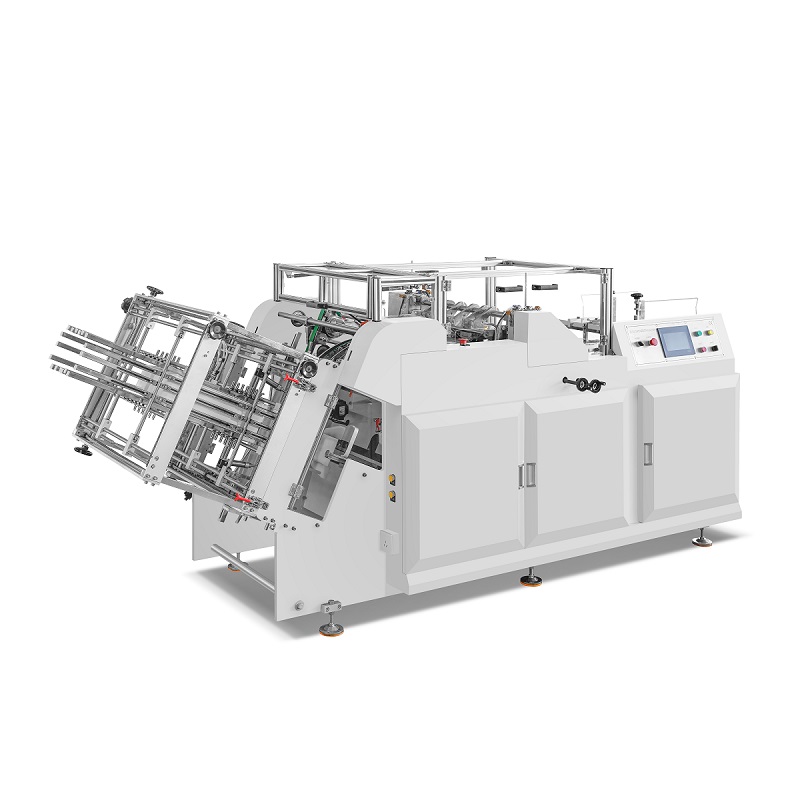

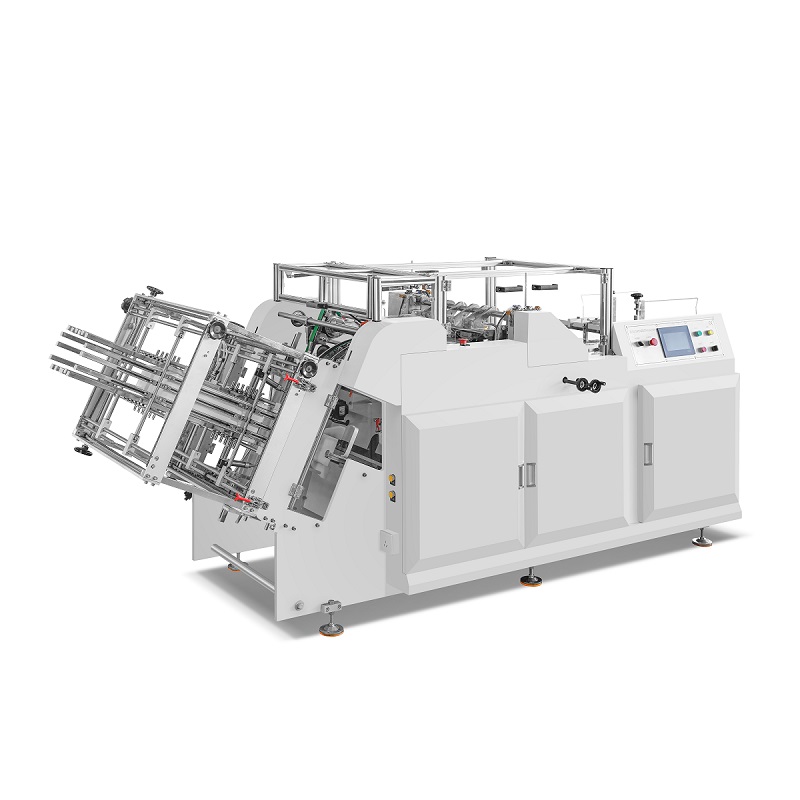

Hiring and training workers for manual packaging is expensive. Automated box-making machines eliminate the need for continuous manual labor, reducing payroll expenses while maintaining consistent output. Machines like Zhixin’s Fast Food Box Making Machine can produce 160pcs/min, significantly lowering production costs for fast-food suppliers.

Key Benefit:

✔ 30–50% cost reduction compared to manual production

✔ Zero downtime from shift changes or human errors

2. Sustainability & Eco-Friendly Packaging Demands

Governments and consumers demand biodegradable and recyclable food packaging. Automated box machines can seamlessly switch between materials like:

- Kraft paper (compostable)

- PLA-coated cardboard (plant-based)

- Recycled fiber (FDA-approved)

Case Study:

Burger King’s switch to 100% recycled paperboard in Europe was made possible with automated box-making technology that adjusts material settings instantly.

3. Faster Turnaround & Scalability

Fast-food chains require high-speed production to meet peak hours (e.g., lunch rushes). Automated machines offer:

✔ Up to 8,000 boxes/hour (vs. 500–1,000 manually)

✔ Custom designs on-demand (brand logos, sizes, fold styles)

✔ Batch switching in seconds (no re-tooling delays)

“McDonald’s suppliers in Asia reduced packaging lead time by 70% after automating box production.”

4. Hygiene & Food Safety Compliance

Automated machines reduce human contact, minimizing contamination risks. Features like touch-free operation, anti-microbial belts, and automated gluing ensure compliance with FDA, ISO 22000, and HACCP standards.

5. Future Trends: AI & Smart Packaging Integration

Leading manufacturers now incorporate:

- AI-powered defect detection (rejects imperfect boxes in real-time)

- IoT monitoring (tracks machine performance & maintenance needs remotely)

- QR code printing (for promotions & supply chain tracking)

Conclusion

Automated fast food box making machines are no longer a luxury—they’re a necessity for chains looking to cut costs, boost sustainability, and streamline production. With advancements in AI, material flexibility, and speed, this technology will dominate the future of food packaging.

Are you a fast-food supplier? Investing in an automated box machine could be your next competitive edge.