In a world where sustainability, efficiency, and practicality are essential, one humble yet revolutionary material stands out — corrugated paper. Though often taken for granted, this wavy-layered cardboard has become the backbone of packaging solutions worldwide, including in the food industry. Among its many applications, the corrugated food paper box is a quiet hero of our daily convenience — from burger wraps to pizza boxes.

So… what exactly is corrugated paper? Why is it everywhere? And what makes a corrugated food paper box so important?

Let’s dive in.

What is Corrugated Paper?

Corrugated paper is a multi-layered material that consists of a fluted (wavy) middle layer sandwiched between two flat linerboards. These layers give corrugated paper its signature rigid-yet-light structure, offering excellent strength, cushioning, and resistance to pressure.

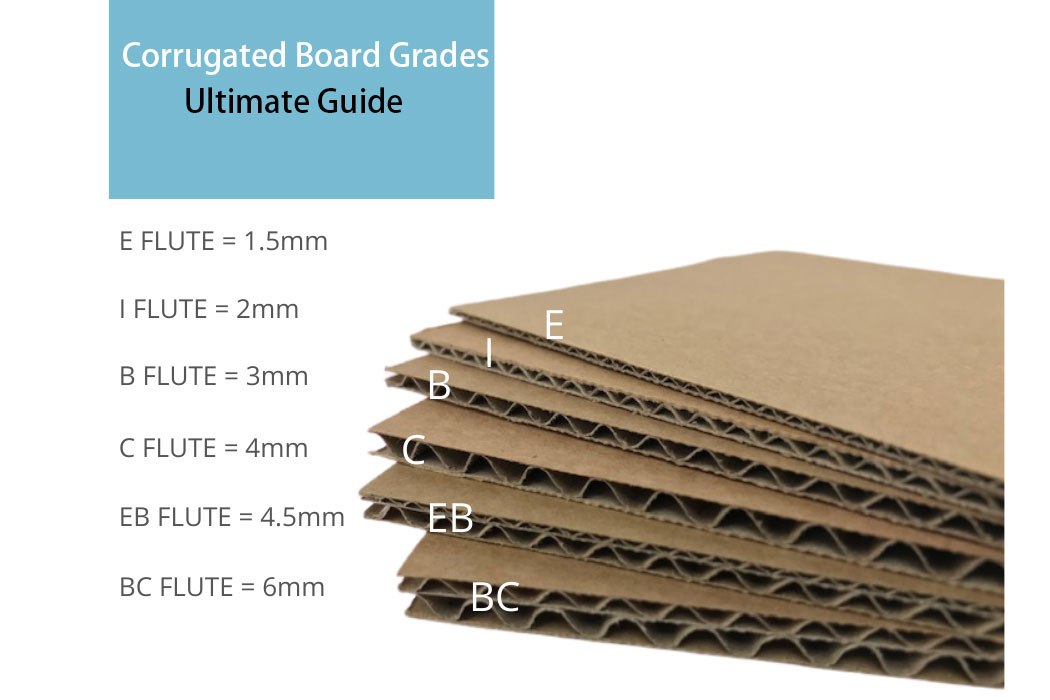

There are different types of flute sizes (like A, B, C, E, F flutes), each offering a different balance of thickness, strength, and printability. Thicker flutes are better for protection, while smaller flutes work better for detailed printing.

Why Corrugated for Food?

Corrugated paper is ideal for food packaging for several key reasons:

1. Structural Strength

Food needs protection during transport — whether it’s a pizza delivery across town or a box of cupcakes shipped nationwide. Corrugated paper provides the cushioning and durability needed to keep food intact and presentable.

2. Customizability

You can easily customize corrugated boxes to different shapes, sizes, and closures — from a slice-of-cake wedge box to a big square fried chicken bucket. They can even include windows, inserts, or partitions depending on the food.

3. Printability

With modern printing techniques like flexo or offset printing, corrugated boxes can carry attractive branding, product info, QR codes, or even fun designs for kids’ meals. The outer layer of corrugated material takes ink well and resists smudging.

4. Food-Safe Coatings

Today’s corrugated boxes can be coated with food-safe linings — like PE (Polyethylene) film for moisture resistance or PLA (Polylactic Acid) film for compostability. This keeps greasy foods from seeping through while keeping packaging sustainable.

5. Sustainability

Most corrugated materials are made from recycled paper and are fully recyclable or compostable. That makes them a great solution for eco-conscious consumers and food companies seeking to reduce plastic waste.

Types of Corrugated Food Paper Boxes

Let’s take a look at some common (and cool) examples you’ve probably seen — or used — this week.

1. Pizza Boxes

Classic square boxes made from E- or B-flute corrugated paper. They’re strong, breathable (thanks to small air holes), and grease-resistant. Some include compartments for sauces or dips.

2. French Fry & Fried Chicken Boxes

Usually made from small-flute corrugated boards with vent holes to prevent sogginess. These boxes often include printed branding and greaseproof inner coatings.

3. Burger Boxes

Folded clamshell boxes using lightweight corrugated with internal coatings. They’re designed for easy stacking, heat insulation, and minimal deformation from steam or moisture.

4. Takeaway Meal Boxes

Full-meal containers with compartments, often microwaveable. Corrugated versions are stronger than single-layer boxes, helping with spill resistance and structural rigidity.

5. Cake & Pastry Boxes

Delicate goods like cakes or pies need stronger, supportive boxes to maintain shape. These often use white coated corrugated with elegant printing and handles.

The Anatomy of a Good Corrugated Food Box

What makes a “good” food box from corrugated paper? Let's break it down:

|

Feature |

Why It Matters |

|

Flute Size |

E or F flute for printability; B flute for strength |

|

Coating |

PE, PLA, or waterproof layer for grease resistance |

|

Design |

Die-cut for easy folding and locking mechanisms |

|

Branding |

Offset or flexo printed artwork and instructions |

|

Certification |

Food-grade materials with contact safety approvals |

Corrugated vs. Non-Corrugated: The Battle of Boxes

Here’s a quick comparison between corrugated paper boxes and single-layer (folding carton) boxes:

|

Category |

Corrugated Box |

Folding Carton Box |

|

Strength |

High – protects heavy/messy food |

Lower – suitable for light items |

|

Insulation |

Good heat retention |

Limited insulation |

|

Cost |

Slightly higher |

Generally lower |

|

Custom Shapes |

Moderate flexibility |

High flexibility |

|

Sustainability |

Highly recyclable |

Also recyclable |

Future of Corrugated Food Packaging

Corrugated paper isn’t standing still — innovation continues:

Water-resistant corrugated materials using natural coatings

Smart packaging with printed QR codes or freshness sensors

Biodegradable glues and no-plastic linings

Ultra-light microflute corrugated for high-end bakery and cosmetics packaging

Summary – Let’s Give It Up for Corrugated!

Corrugated food paper boxes are simple, humble, and heroic. Whether it’s holding your juicy burger, your favorite pizza, or your weekend sushi set, corrugated packaging makes life more convenient — and more sustainable.

GET A QUOTE

+86-13780131993