Kraft paper has become a go-to material in the packaging world—especially in the food industry—due to its versatility, eco-friendliness, and natural look. From takeaway boxes to sandwich wraps, kraft paper is not just a packaging trend, but a smart, sustainable solution.

What Is Kraft Paper?

Kraft paper is a type of paper produced through the kraft process, a chemical pulping method that turns wood into strong pulp fibers. The result? A durable, tear-resistant, and biodegradable paper that retains a natural brown color (although it can also be bleached to white).

The word "kraft" actually comes from the German word for “strength”—which is exactly what this paper offers.

Key Features That Make Kraft Paper Ideal for Food Packaging

High Tensile Strength

Kraft paper is resistant to tearing, making it ideal for food boxes that need to maintain shape even when holding greasy or heavy items.

Natural and Food-Safe

Unbleached kraft paper is free from toxic chemicals, making it a safe choice for direct food contact.

Grease-Resistant Coating (Optional)

Kraft paper can be laminated with PE (polyethylene) or coated with food-grade wax or PLA to provide oil and water resistance.

Eco-Friendly

It’s recyclable, biodegradable, and compostable—one of the most sustainable options on the packaging market.

Excellent Printability

It absorbs ink well, allowing companies to showcase branding and labeling in a rustic, organic style.

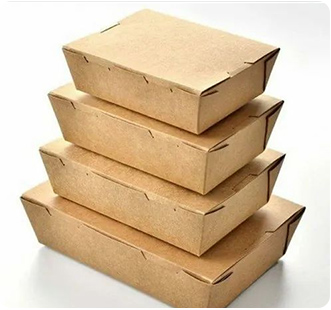

Common Kraft Paper Box Applications

Kraft paper is widely used across many food categories. Here's where you'll often see it:

Burger boxes

Fried food trays

Salad containers

Wrap paper for sandwiches

Bakery boxes

Pizza slice trays

Biodegradable bento boxes

Kraft Paper vs. Other Packaging Papers

|

Feature |

Kraft Paper |

Corrugated Paper |

White Cardboard |

|

Strength |

High |

Very High |

Medium |

|

Surface Smoothness |

Medium |

Low (outer layer only) |

High |

|

Printability |

Good |

Average |

Excellent |

|

Grease Resistance |

With coating |

Often laminated |

Often laminated |

|

Sustainability |

Excellent |

Good |

Good |

What’s Behind the Strength of Kraft?

Unlike recycled papers, kraft paper is made using virgin wood pulp, which means the fibers are long and intact. This increases tensile strength and ensures the material holds up even when exposed to moisture or oil.

Additionally, the absence of harsh chemical bleaching means kraft paper keeps most of the wood’s original lignin, giving it a natural resistance to moisture and decomposition.

Kraft Paper in the Production Line

In paper box forming machines (such as burger box or fry box machines), kraft paper behaves well on feeding rollers and shaping molds due to its flexibility and strength. Whether used as single-wall wrapping or laminated into multilayer containers, it delivers solid forming quality and edge-crimping performance.

Why Brands Love Kraft Paper Boxes

Aesthetic Appeal

Its natural, rustic appearance gives brands an eco-conscious image.

Customizable

Works well with soy-based inks, die cuts, window patches, and embossing.

Regulation-Ready

Complies with most global food safety and compostability standards (e.g., FDA, EU).

Points to Watch

Moisture Sensitivity: Uncoated kraft paper may absorb water or oil. Always consider PE or PLA coating if your product is wet or greasy.

Color Inconsistency: Natural kraft may have slight color variations batch-to-batch.

Trends in Kraft Packaging

Hybrid Kraft Packaging: Blending kraft with corrugated or white board for strength and brand clarity.

Compostable Laminates: PLA and water-based coatings replacing PE for 100% biodegradability.

QR Code Printing: Brands are embedding scannable codes for traceability or promotion—yes, even on kraft!

Final Thoughts

Kraft paper is the workhorse of eco-friendly food packaging. It’s cost-effective, durable, and sustainable—a trifecta that manufacturers and eco-conscious brands both love. Whether you're forming wrap-around fry boxes or sturdy burger clamshells, kraft paper delivers on strength, simplicity, and style.

GET A QUOTE

+86-13780131993