In today’s fast-paced manufacturing and logistics industries, efficiency and automation are key to maintaining productivity. One essential piece of equipment that plays a crucial role in packaging operations is the carton erecting machine .These machines automate the process of forming cardboard boxes from flat blanks, significantly reducing labor costs and increasing packaging speed.

However, with various models and configurations available, selecting the right carton erecting machine can be challenging. This guide will help you understand the key factors to consider when choosing the best machine for your business.

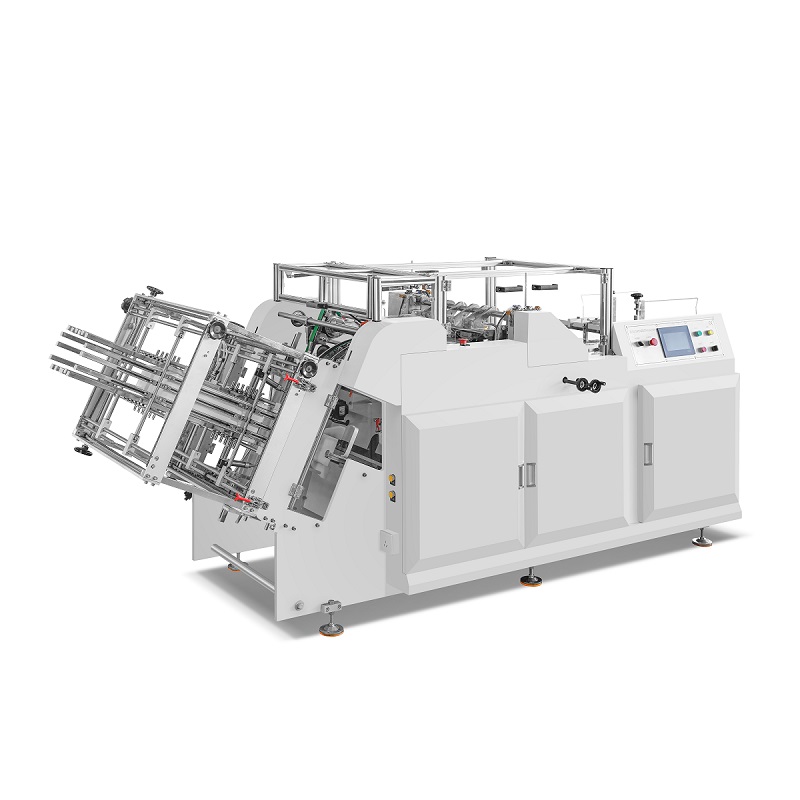

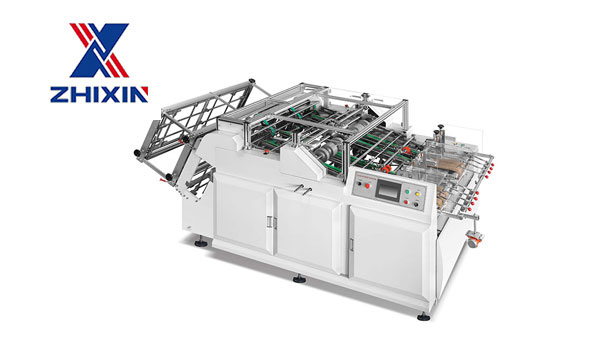

What Is a Carton Erecting Machine?

A carton erecting machine is an automated system designed to take flat cardboard sheets (carton blanks) and fold them into ready-to-use boxes. These machines are widely used in industries such as:

E-commerce & retail

Food & beverage

Pharmaceuticals

Electronics

Logistics & warehousing

By automating box formation, businesses can streamline their packaging lines, reduce manual labor, and improve consistency in box quality.

Key Factors to Consider When Choosing a Carton Erecting Machine

1. Production Speed & Capacity

Different carton erecting machines offer varying speeds, typically measured in boxes per minute (BPM). Consider your production volume:

Low to medium volume (10-30 BPM): Ideal for small businesses or operations with moderate packaging needs.

High-speed (30-60+ BPM): Suitable for large-scale manufacturers and distribution centers.

2. Box Size & Compatibility

Ensure the machine can handle the range of box sizes your business requires. Key considerations include:

Minimum and maximum dimensions (length, width, height)

Adjustability – Can the machine quickly switch between different box sizes?

Material thickness – Some machines may struggle with very thick or rigid corrugated cardboard.

3. Automation Level

Carton erectors come in different automation levels:

Semi-automatic: Requires some manual feeding or adjustment; best for low-budget operations.

Fully automatic: Integrates seamlessly with conveyors and other packaging machinery for a fully automated line.

4. Integration with Other Packaging Equipment

If your packaging line includes other machines (e.g., fillers, sealers, labelers), ensure the carton erecting machine can integrate smoothly. Look for features like:

Conveyor compatibility

PLC (Programmable Logic Controller) connectivity

Barcode or RFID scanning for smart packaging

5. Durability & Maintenance

A high-quality carton erecting machine should be built to last with minimal downtime. Consider:

Construction materials (stainless steel vs. standard metal)

Ease of maintenance (quick-access panels, self-lubricating parts)

Vendor support & warranty

6. Budget & ROI

While automation improves efficiency, it’s important to balance cost with benefits. Evaluate:

Upfront cost vs. long-term labor savings

Energy efficiency

Potential for future upgrades

Types of Carton Erecting Machines

Conclusion

Before making a purchase, ask the supplier to test your actual cartons on the machine. This ensures no surprises—you’ll see how well it handles your size, material, and style, and confirm the speed meets your needs.

Choosing the right Carton Erecting Machine isn’t just about buying equipment—it’s about investing in the efficiency and growth of your packaging operations. By following these steps, you’ll select a machine that fits your current needs and adapts to your future goals.