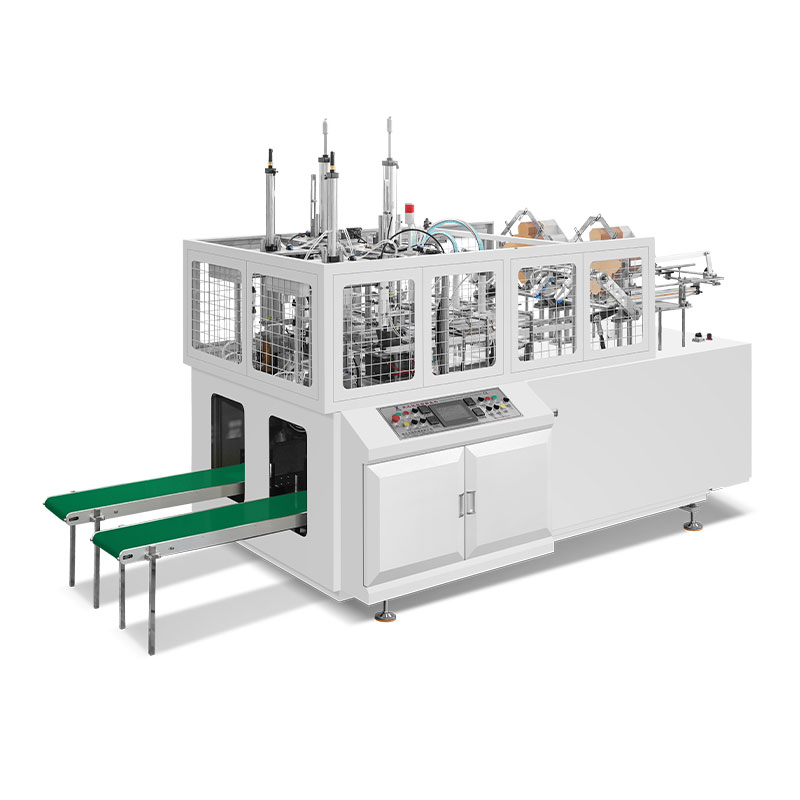

Double Station TakeAway Box Machine for Restaurant takeaway boxes

Zhejiang Zhixin Machinery, a leading global provider of automated packaging solutions, introduces its Double Station TakeAway Box Machine—the ultimate solution for restaurants and food chains seeking high-speed, flexible, and eco-friendly takeaway packaging. Designed to meet the dynamic demands of modern food service, these machines combine dual-station productivity with advanced technology, enabling restaurants to deliver consistent, sustainable packaging at scale.

1. Unmatched Speed for Peak Service Hours

The core advantage of Zhixin’s double-station design lies in its parallel production capability. Models like the ZX-1200 can produce up to 180 pieces per minute across two independent lines, doubling output compared to traditional single-station machines. This is critical for restaurants during lunch or dinner rushes, where demand for takeaway boxes can surge by 300%.

- Rapid mold switching: Thanks to PLC program control, operators can switch between box sizes (e.g., from burger boxes to family meal containers) in under 5 minutes, minimizing downtime and adapting to sudden menu changes.

- Servo-driven precision: The full servo system ensures ultra-accurate folding and gluing, with dimensional tolerances within ±0.5mm, even at high speeds. This consistency is vital for brands like KFC, which rely on uniform packaging for brand integrity.

2. Versatile Materials for Sustainability and Functionality

Zhixin machines excel in handling a wide range of eco-friendly materials, aligning with global sustainability goals:

- Food-grade cardboard (200–620 GSM): Ideal for standard burger boxes and noodle containers, offering rigidity and printability for vibrant brand logos.

- Corrugated paper: Used for heavy-duty applications like multi-layer lunch boxes, providing 40% better compression resistance than traditional plastic.

- PLA-coated composites: For oily or hot foods (e.g., fried chicken), these plant-based materials ensure leak-proof seals and are fully compostable within 6–12 months.

Restaurants like Burger King have leveraged Zhixin’s technology to transition to 100% recycled paperboard packaging in Europe, reducing their carbon footprint by 40% while maintaining structural integrity.

3. Customization for Diverse Menu Needs

Modern restaurants thrive on variety, and Zhixin’s double-station machines deliver on-demand customization:

- Size flexibility: Produce boxes ranging from small sauce containers (100mm×100mm) to large family trays (450mm×600mm) on the same line.

- Complex structures: The machines handle 3D designs like clamshell boxes, partitioned lunch boxes, and tamper-evident seals, ensuring food safety and convenience.

- Branding integration: High-resolution printing supports detailed logos and promotional graphics, enhancing brand visibility. For example, Subway uses Zhixin machines to print regional designs on sandwich boxes, boosting customer engagement.

4. Hygiene, Compliance, and Operational Savings

- Touch-free automation: the entire process is fully automated, reducing human contact and meeting FDA, ISO 22000, and HACCP standards.

- Cost efficiency: Compared to manual production, Zhixin’s machines reduce labor costs by 30–50% and material waste by 25%, thanks to precise servo-controlled material feed.

- Global support: With a 1-year warranty, lifetime maintenance, and 24/7 technical service, restaurants in over 60 countries (including China’s Wallace and global chains like Pizza Hut) rely on Zhixin for uninterrupted production.

As restaurants worldwide prioritize sustainability and operational agility, Zhixin’s Double Station TakeAway Box Machines stand as the definitive solution—delivering speed, customization, and eco-friendliness in every box.

Elevate your takeaway packaging with Zhixin—visit www.zhixinmachine.com to discover how our dual-station technology can transform your restaurant’s packaging efficiency.