If you’re in the disposable food packaging business, you’ve felt the pressure: global “ban plastic” policies are tightening, consumers are choosing eco-friendly options, and traditional plastic lunch box sales are plummeting. But here’s the good news—PE coated paper lunch box machine() is your solution. This totally eco-friendly equipment turns biodegradable paper into high-quality, oil-resistant lunch boxes that meet global environmental standards. Today, we’ll show you why this machine is a must-have in 2025, how it cuts costs, and how to pick the right model for your business.

Why Eco-Friendly PE Coated Paper Lunch Boxes Are Taking Over the Market

First, let’s clear up a common question: Is PE coated paper lunch box really eco-friendly? Yes! Unlike plastic (which takes 450+ years to decompose), PE coated paper lunch boxes use:

-

Biodegradable base material: The core is food-grade kraft paper, which decomposes naturally in 3–6 months.

-

Food-safe PE coating: The thin PE layer (polyethylene) is non-toxic, recyclable, and doesn’t leach harmful chemicals—even when holding hot food.

This combination makes PE coated paper lunch boxes compliant with strict regulations:

- EU’s Single-Use Plastics Directive (SUPD)

- US FDA food contact standards

- China’s “14th Five-Year Plan” for plastic reduction

And the market demand? It’s booming. A 2024 report shows global eco-friendly food packaging sales will grow 22% this year—with PE coated paper lunch boxes leading the category. If you don’t switch to eco-friendly PE coated paper lunch box machine now, you’ll miss out on this $50B market.

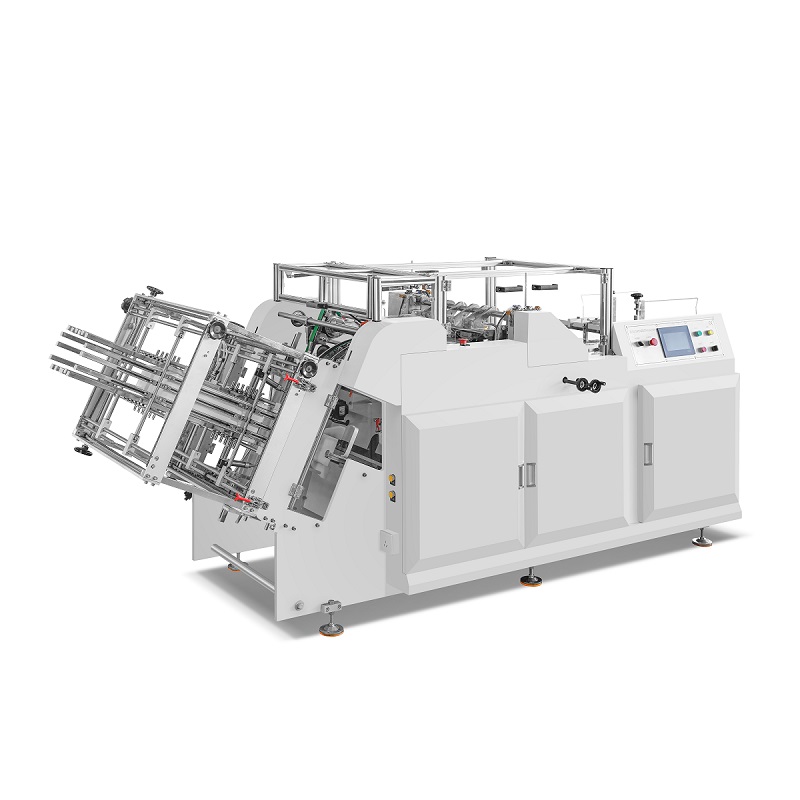

PE Coated Paper Lunch Box Machine

What Makes Our PE Coated Paper Lunch Box Machine “Totally Eco-Friendly”?

Not all PE coated paper lunch box machines are the same. Ours stands out for 3 green advantages that save you money and boost your brand:

1. 98% Raw Material Utilization (No Waste, Low Costs)

Traditional machines waste 10–15% of paper due to imprecise cutting. Our PE coated paper lunch box machine uses computer-controlled die-cutting technology to maximize material use. For example:

-

A 1m x 1.2m PE coated paper sheet makes 12 standard lunch boxes (vs. 10 with old machines).

-

Annual savings: If you produce 50,000 boxes/day, you’ll cut paper costs by $12,000/year.

And the waste we do generate? It’s 100% recyclable—you can sell it to paper mills for extra income.

2. Low Energy Consumption (30% Less Than Traditional Models)

Eco-friendly doesn’t mean high energy bills. Our machine uses:

-

Variable-frequency motors that adjust power based on production speed (saves 15% energy).

-

Heat-recovery systems that reuse excess heat from the PE coating process (saves another 15%).

Total energy savings: 30%. For a machine running 16 hours/day, that’s $800/month less in electricity costs.

3. Zero Wastewater, Zero Harmful Emissions

Unlike plastic lunch box machines (which release toxic fumes), our PE coated paper lunch box machine has:

-

A closed-loop exhaust system that filters PE fumes (meets EU’s VOC emission standards).

-

No water use in production (traditional machines need water for cooling—we use air cooling instead).

This means you won’t need expensive wastewater treatment equipment, and you’ll pass environmental inspections easily.

More Than Eco-Friendly: High Efficiency for All Business Sizes

We know you care about more than just sustainability—you need to meet orders fast. Our PE coated paper lunch box machine comes in 3 models to fit your needs:

| Model | Hourly Output | Ideal For | Price Range |

|---|---|---|---|

| Mini-500 | 500–800 boxes | Small businesses, startups | $18,000–$25,000 |

| Pro-1200 | 1,200–1,500 boxes | Medium factories | $35,000–$45,000 |

| Max-2000 | 2,000–2,500 boxes | Large-scale production | $60,000–$75,000 |

All models have automatic feeding, coating, cutting, and stacking—so 1 worker can operate 2 machines at once. A client in Malaysia switched to our Pro-1200 model and increased production by 40% with the same number of staff.

How a Plastic Box Maker Switched to Eco-Friendly and Doubled Profits

Mr. Tan, owner of a packaging factory in Vietnam, used to make plastic lunch boxes. In 2023, Vietnam’s plastic ban forced him to pivot. He bought our eco-friendly PE coated paper lunch box machine and:

-

Cut material costs by 18% (thanks to high utilization).

-

Landed a $200,000/year order from a global fast-food chain (they needed eco-friendly packaging).

-

Doubled his profit margin (PE coated paper boxes sell for 30% more than plastic).

“We didn’t just comply with the ban—we grew our business,” Mr. Tan said. “The machine paid for itself in 6 months.”

Ready to Switch to Totally Eco-Friendly PE Coated Paper Lunch Box Machine?

Here’s what you get when you work with us:

-

Free site inspection: We’ll visit your factory to design the best production line layout.

-

3-day on-site training: Teach your staff to operate, maintain, and troubleshoot the machine.

-

1-year warranty: Cover all parts (except wear-and-tear items) and free technical support 24/7.

-

Raw material recommendations: Connect you with trusted PE coated paper suppliers at wholesale prices.

Don’t let plastic bans or competition slow you down. The PE coated paper lunch box machine is your ticket to eco-friendly compliance, lower costs, and bigger profits.

Contact us today for a free quote and a video demo of the machine in action. Let’s build your sustainable packaging business—together.