Paper Plate Making Machine: Your Complete Buying Guide

The global demand for disposable paper plates is soaring—driven by restaurants, caterers, picnic events, and eco-conscious consumers ditching plastic. If you’re looking to start a paper plate production business or upgrade your existing equipment, choosing the right Paper Plate Making Machine is the first (and most critical) step. But with countless models on the market—from semi-automatic to fully automatic, low-capacity to industrial-grade—how do you avoid costly mistakes and pick a machine that fits your goals? This complete guide breaks down everything you need to know.

Clarify Your Production Needs First

Before browsing machines, define your core requirements—this will narrow down your options and prevent overspending. Focus on these 3 key factors:

1. Daily/Monthly Production Volume

Your output goals directly determine the machine’s size and speed. Ask yourself:

-

Small-scale (1,000–5,000 plates/day): Ideal for home-based businesses or local supply (e.g., serving 10–20 small restaurants). A semi-automatic machine works here.

-

Medium-scale (5,000–20,000 plates/day): Suits regional suppliers or growing catering businesses. Opt for a fully automatic machine with moderate speed.

-

Large-scale (20,000+ plates/day): For industrial operations supplying supermarkets or national food chains. Choose a high-speed, multi-station automatic machine.

Pro tip: Add a 20% buffer to your target volume—this accounts for maintenance downtime or sudden order surges.

2. Paper Plate Specifications

Paper plates vary in size, shape, and material—ensure the machine can handle your desired products:

-

Size: Common sizes range from 6-inch (snack plates) to 12-inch (dinner plates). Pick a machine with adjustable molds or compatible mold sets for future size expansions.

-

Shape: Round plates are standard, but some machines support square, oval, or custom shapes (great for niche markets like party supplies).

-

Material: Most machines use kraft paper, coated paper (for oil-resistant plates, e.g., for fried food), or sugarcane bagasse paper (eco-friendly option). Confirm the machine’s compatibility—coated paper may require a heated press to avoid peeling.

3. Available Space & Power Supply

Paper plate machines come in different footprints:

-

Semi-automatic machines: Compact (1.5m × 1m × 1.2m), fit in garages or small workshops.

-

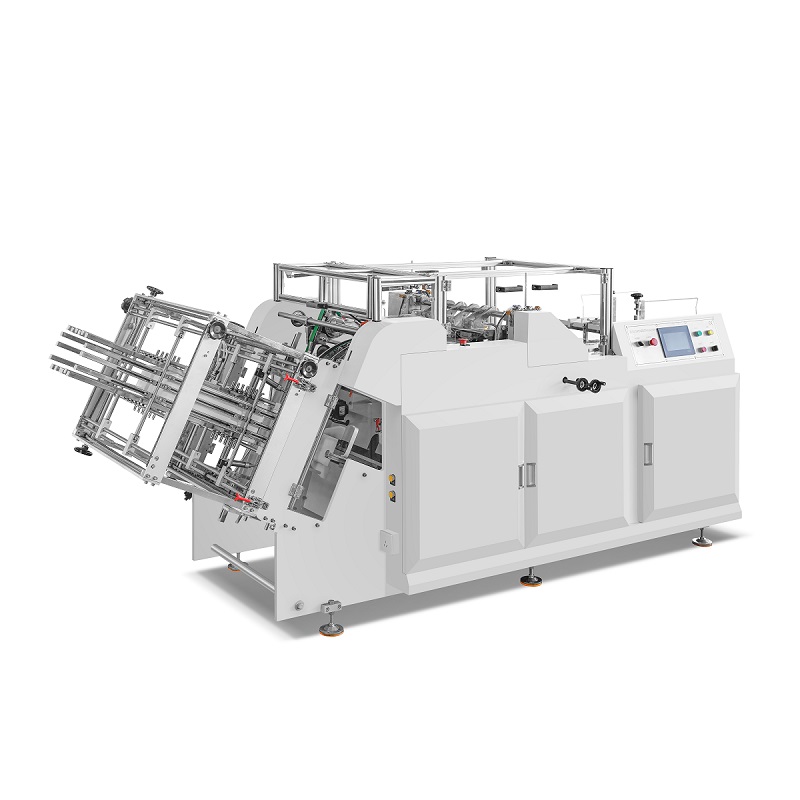

Fully automatic machines: Larger (3m × 1.5m × 1.8m), need dedicated factory space.

Also, check power requirements—most machines use 220V (for small models) or 380V (for industrial models). Ensure your workshop has the right wiring to avoid electrical issues.

Choose the Right Machine Type (Semi-Automatic vs. Fully Automatic)

The two main types of Paper Plate Making Machines differ in automation level, labor needs, and cost. Here’s how to compare them:

|

Feature |

Semi-Automatic Paper Plate Machine |

Fully Automatic Paper Plate Machine |

|

Operation |

Requires manual feeding of paper and removing finished plates. |

Fully automated (paper feeding → molding → pressing → stacking). |

|

Production Speed |

30–60 plates/minute (1,800–3,600/day) |

80–150 plates/minute (4,800–9,000/hour) |

|

Labor Needs |

1–2 workers |

0–1 worker (only for monitoring/stacking) |

|

Cost Range |

\(1,500–\)5,000 |

\(8,000–\)30,000+ (industrial models) |

|

Best For |

Beginners, small batches, tight budgets |

High-volume production, cost savings long-term |

Key consideration: If you plan to scale within 1–2 years, invest in a fully automatic machine upfront—upgrading later will cost more than buying the right model now.

Evaluate Core Components & Performance

Not all machines are built the same—focus on these critical parts to ensure durability and quality output:

1. Molding & Pressing Unit

This is the “heart” of the machine, responsible for shaping the paper into plates:

-

Mold Material: Look for stainless steel molds (resistant to rust and wear) instead of aluminum (prone to bending). Replaceable molds are a plus—they let you switch plate sizes/shapes without buying a new machine.

-

Pressing Pressure: A machine with adjustable pressure (5–15 tons) works for different paper thicknesses. Too little pressure = weak plates; too much = paper tearing.

2. Heating System

For oil-resistant or coated paper plates, a reliable heating system is essential:

-

Heating Plates: Choose machines with electric heating plates (even heat distribution) over gas-powered ones (higher safety risks).

-

Temperature Control: Digital thermostats (100–200°C) let you adjust heat based on paper type—critical for avoiding burnt edges or unbonded layers.

3. Motor & Drive System

A high-quality motor ensures consistent speed and long machine life:

-

Motor Power: 1.5HP–3HP for semi-automatic models; 5HP–10HP for fully automatic ones. Opt for brands like Siemens or Bosch (less prone to breakdowns).

-

Drive Type: Gear-driven systems are more durable than belt-driven ones (belts need frequent replacement).

4. Safety & User-Friendly Features

-

Emergency Stop Button: Must be easily accessible to halt the machine if paper jams or errors occur.

-

Safety Guards: Transparent covers over moving parts (e.g., feeding rollers) prevent worker injuries.

-

Touchscreen Control: Intuitive interfaces let you set speed, temperature, and plate count—ideal for workers with minimal training.

Select a Reliable Manufacturer (Avoid Scams!)

The manufacturer can make or break your experience—here’s how to pick a trustworthy one:

1. Check Credentials

-

Certifications: Look for ISO 9001 (quality management) and CE (safety) certifications—these ensure the machine meets global standards.

-

Factory Visit: If possible, visit the manufacturer’s facility (or ask for a video tour) to see production quality. Avoid “traders” who don’t own a factory—they can’t provide after-sales support.

2. Ask for Demos & References

-

Live Demo: Request a demo with your desired paper type—watch for consistent plate quality (no cracks, even edges) and smooth operation.

-

Customer References: Ask for contacts of existing buyers (preferably in your region). Call them to ask: “How often does the machine break down?” “Is after-sales support fast?”

3. Evaluate After-Sales Service

Paper plate machines need regular maintenance—ensure the manufacturer offers:

-

Installation & Training: On-site installation (free or low-cost) and worker training (critical for fully automatic models).

-

Warranty: A minimum 1-year warranty for parts (motor, heating plates) and 6 months for labor. Extendable warranties are a bonus.

-

Spare Parts Availability: Local or fast-shipping spare parts (e.g., molds, heating elements)—waiting weeks for parts will stop your production.

Calculate Cost & Return on Investment (ROI)

Don’t just look at the upfront price—calculate the total cost and ROI to ensure profitability:

1. Total Cost Breakdown

-

Machine Price: As listed earlier (semi-automatic: \(1,500–\)5,000; fully automatic: \(8,000–\)30,000).

-

Operating Costs: Electricity (\(0.5–\)2/hour), paper raw materials (\(0.01–\)0.03 per plate), labor (\(10–\)20/day for semi-automatic).

-

Maintenance Costs: \(200–\)500/year (oil changes, spare parts).

2. ROI Estimation

Let’s take a medium-scale example:

-

Machine: Fully automatic ($15,000), 100 plates/minute (6,000/hour, 48,000/day).

-

Cost per plate: $0.02 (material + electricity).

-

Selling price per plate: $0.05 (wholesale to restaurants).

-

Daily profit: 48,000 × (\(0.05 – \)0.02) = $1,440.

-

Monthly profit (25 days): $36,000.

Result: ROI in ~1 month—this shows why choosing the right machine (for your volume) is key to fast returns.

Common Mistakes to Avoid

-

Buying a “Cheap” Machine: Low-cost machines (<$1,000) often use poor-quality parts—they break down frequently, leading to lost production.

-

Ignoring Mold Compatibility: A machine with non-replaceable molds limits your ability to expand into new plate sizes.

-

Forgetting After-Sales Support: A machine without reliable support is useless if it breaks down—don’t risk it for a $500 discount.

Final Checklist for Buying

Before making a purchase, confirm these:

My production volume matches the machine’s speed.

The machine supports my desired plate size/material.

The manufacturer has certifications and positive references.

After-sales service includes installation, training, and a warranty.

The total cost aligns with my budget and ROI goals.

Investing in the right Paper Plate Making Machine is the foundation of a profitable business. By following this guide, you’ll avoid common pitfalls and choose a machine that grows with your needs—whether you’re starting small or scaling to industrial production. Ready to take the next step? Reach out to trusted manufacturers for custom quotes, and don’t forget to request a demo with your own paper material!