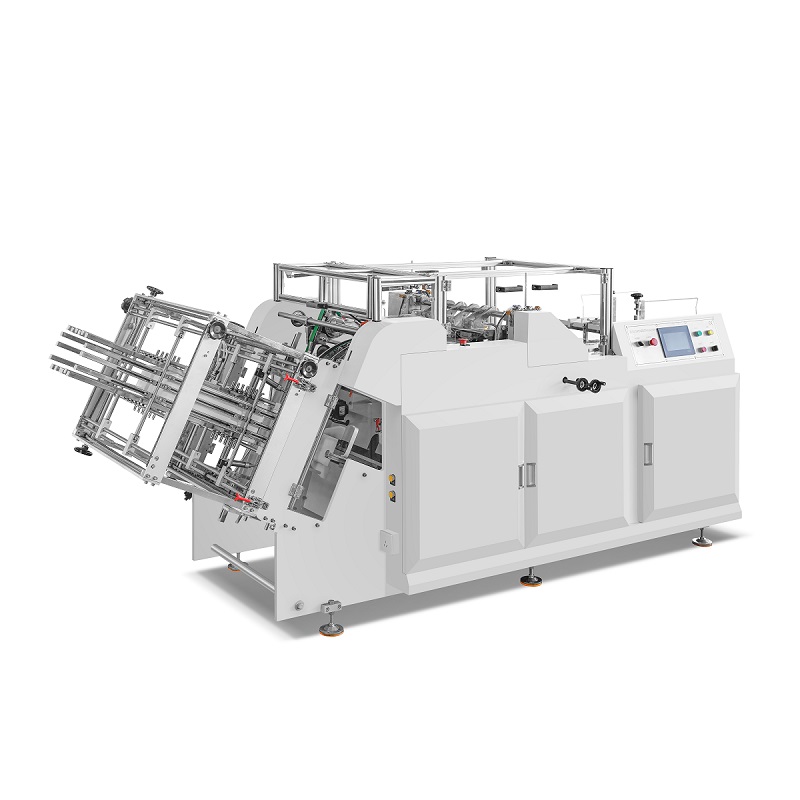

Carton erecting machine is specially designed for fast-food packaging, such as burger boxes, freis boxes, boat trays,and triangular pizza boxes. This article takes the ZX-1200 carton erecting machine as an example to introduce its main technical parameters.

The equipment offers strong adaptability to paper materials, handling paper weights ranging from 180g to 400g and thicknesses from 0.3mm to 1.5mm. It supports a wide processing size range, with a minimum of 120 × 120mm and a maximum of 600 × 500mm, meeting the production needs of various carton specifications. The machine operates efficiently, with an adjustable production speed of 30–160 pieces per minute.

In terms of power and energy consumption, the required working air pressure is 0.5 MPa. It runs on a 380 V three-phase industrial power supply, with a rated current of 12 A and a total power of 2.5 kW. The power frequency is compatible with both 50 Hz and 60 Hz. The machine features a sturdy structure, weighing approximately 1,400 kg, with overall dimensions of 3,500 × 1,350 × 1,500 mm.All key motion axes of this equipment are equipped with a drive system consisting of fully servo motors and matching drives produced by Schneider Electric.

The core advantages of the machine include:

Strong versatility—it accurately adapts to multiple fast-food box types with quick and easy mold changeover.

High efficiency and stability—even at high speeds, it ensures precise forming and strong adhesion.

User-friendly operation—with a high degree of automation, it significantly reduces labor dependency and production costs, making it an ideal solution for enhancing the efficiency of fast-food packaging lines.

Choosing the ZX-1200 carton erecting machine means choosing efficiency and reliability! Let us help you automate your packaging process—delivering consistent quality and faster throughput to keep up with ever-growing market demands.